-

Email Us info@cristochains.com

-

Call Us (+91)-94172-43289

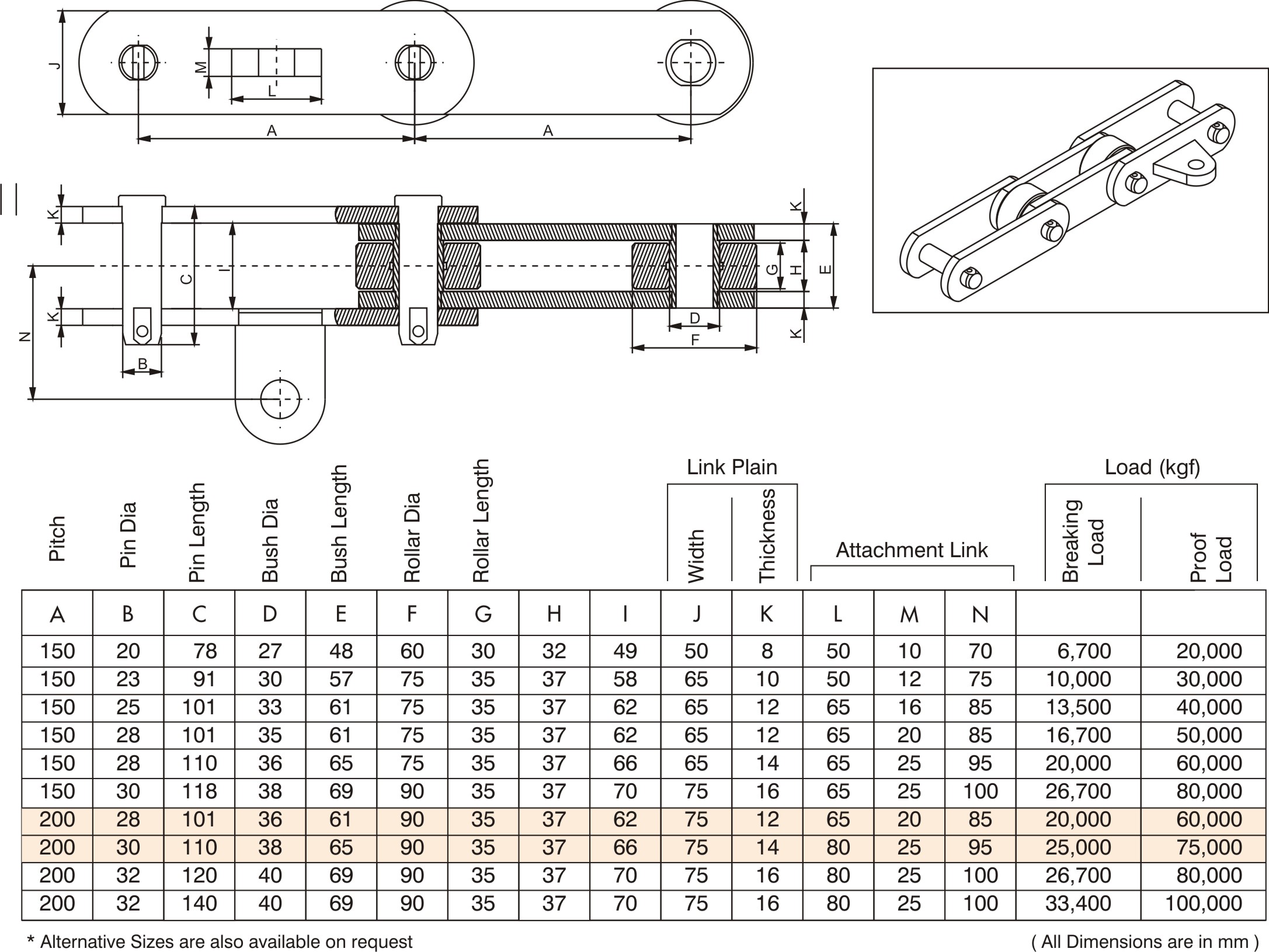

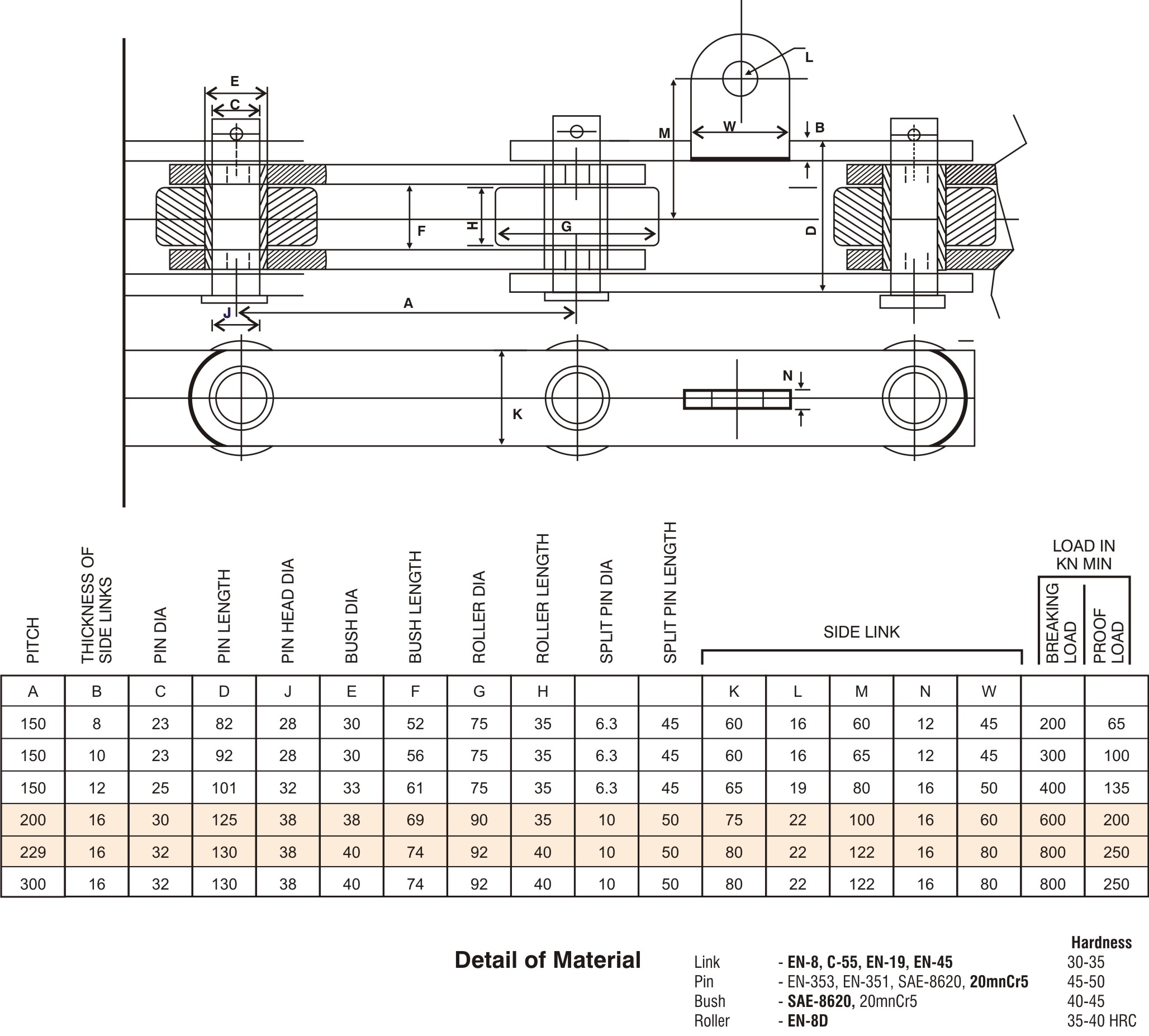

These Bagasse carrier chains are recommended for conveying heavy loads of bagasse over long distances. A wide variety of chains are available with tensile strength ranging from 20,000 to 80,000 Kgs. as per (IS-8466 : 1990)

The wide variety of Conveyor chains are manufactured with Breaking Strength in the range from 20,000 kgf. to 100,000 kgf. These chains are commonly used in Sugar Industries, to convey or feed Bagasse to either Boiler or to storage point.

Chain links are made from Carbon steel. These links are subjected to operations like Blanking, Piercing & Shaving, which are carried out on highly Precised Presses. Further links are Hardened & Tempered to avoid linear elongation & to get better strength. The process followed by shot peening to improve the fatigue strength.

Pin & Bushes are made from Low Carbon alloy steel with precision machining. Case Carburizing, Hardening & Tempering processes are carried out to increase the Wear resistance & Core strength, Then ground finishing is done for perfect fitting.

Rollers are made from Medium carbon steel & are subjected to Heat Treatment process to improve the wear resistance.

These chains are also manufactured & supplied in heat treated Stainless Steel material, with 2C flights as per requirement & normally called as A42 or AS2 Attachment chains.

These chains are also known as :