-

Email Us info@cristochains.com

-

Call Us (+91)-94172-43289

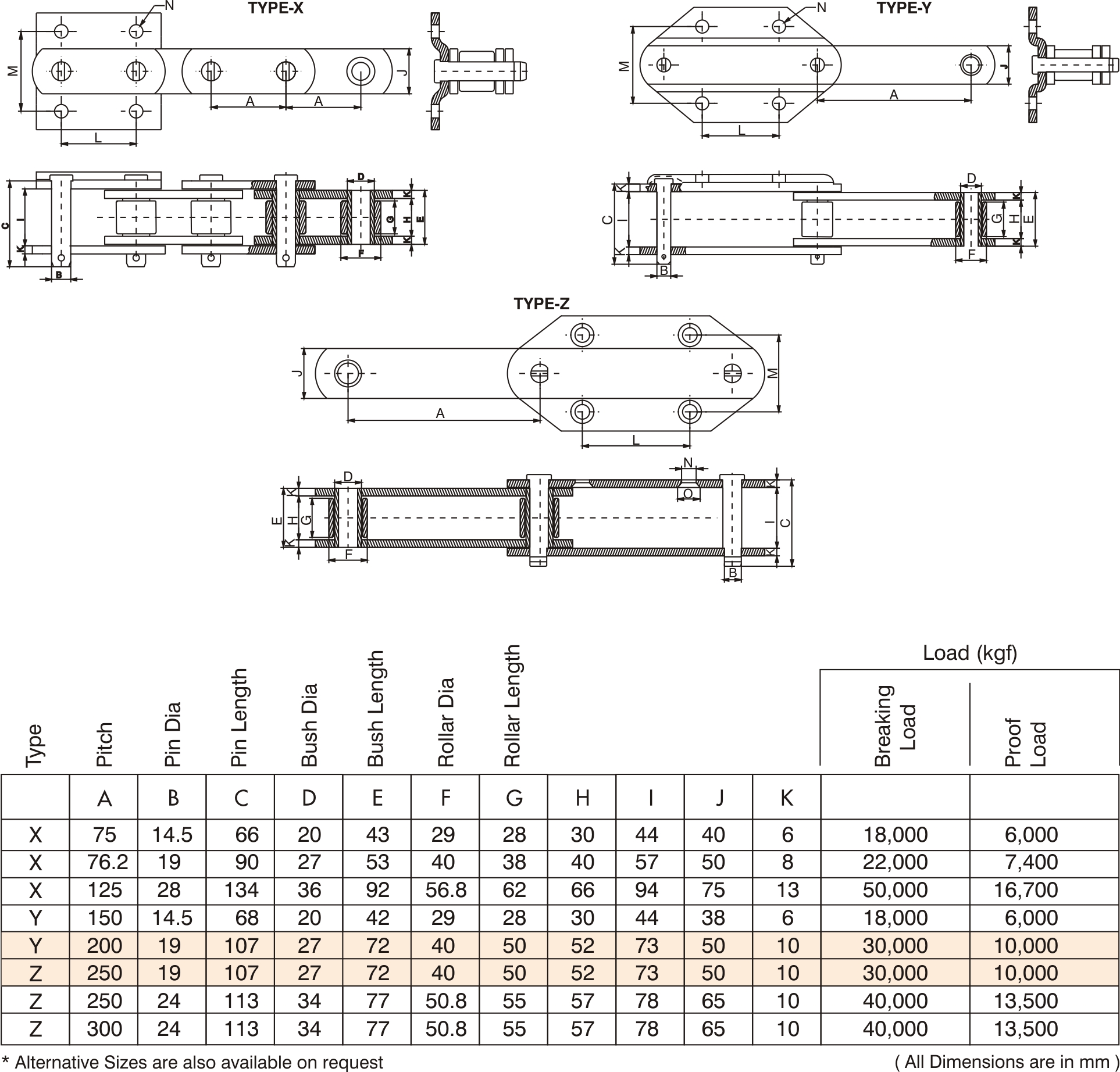

Different designs & sizes of Bucket Elevator Chain are used in Cement, Power & Fertilizers Industries etc. to lift material depending on height & load carrying capacity. The chain material is designed to withstand against high abrasion & dusty condition.

Chain links are made from Medium Carbon / Alloy Steel. These links are subjected to operations like Blanking & fine boring, which are carried out on highly precision machines. The link hole size & finishing is controlled to suit adequate interference fit. Further links are hardened & tempered to avoid linear elongation & to get better impact strength followed by shot peening process to improve the fatigue strength.

Special Alloy Steel is used for Pins with Volume Hardened & Tempered to get the maximum core strength & followed by Induction Hardening to achieve armored case depth for maximum wear resistance.

Special Alloy Steel is used for Bushes with adequate heat treatment. Optimum case depth is achieved to provide maximum wear resistance & core strength by Case Carburizing. Medium Carbon / Alloy Steel is used for Rollers with Appropriate Heat Treatment.

In Fertilizer industries, since the Chain are working in highly alkaline conditions, special grades of material are selected & heat treated to with-stand in such condition. As the corrosion resistance properties are improved, better life of chain is assured.